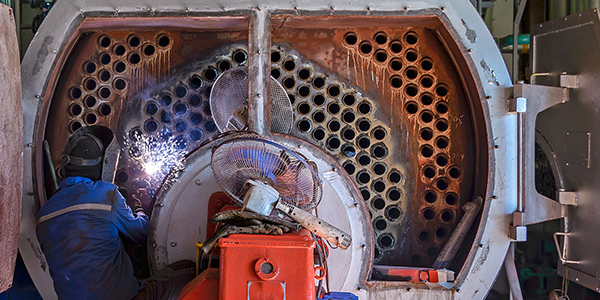

When your boiler or pressure-retaining equipment breaks down, it is critical you get them repaired quickly to get your plant back into production. While you may be on a tight budget and have maintenance people available, you need a qualified industrial boiler repair contractor to ensure safe and efficient functioning. The following are the three most important factors to consider when hiring an industrial boiler repair.

Are they a certified industrial boiler repair contractor?

A quality boiler repair process requires proper training, knowledge, and hands-on experience. It also requires certification. Therefore, before you hire an industrial boiler repair contractor, make sure that you check they have R Stamp certification. A contractor earns an ‘R’ stamp from the National Board of Boiler and Pressure Vessel Inspectors. It certifies a contractor meets the qualification requirements for alterations or repairs. In order to earn and maintain the National Board of Boiler and Pressure Vessel R Stamp certification, a contractor must pass a detailed and strenuous certification process. Once this testing and certification process is complete, the welder and the contractor have to keep in good standing with the National Board. If an industrial boiler repair contractor doesn’t comply with these guidelines, or non-qualified individuals do repairs, there is the potential to create hazardous conditions for your manufacturing facility and the public.

What is their experience level?

Mainly, the more experience of the industrial boiler repair contractor, the better the quality of work you can expect. However, years of working on boilers are only part of the criteria. You need to ask the type of experience they have. For example, have they worked on your type of boiler, pressure vessels, or pressure retaining equipment? It is important for the contractor to have specific knowledge and understanding of your equipment. This experience, along with R Stamp certification, will help to assure the repairs to your equipment are correct. When you confirm the type and length of the contractor’s experience, you avoid mishandled repairs, unnecessary repairs, and potential risk.

What is their reputation?

The reputation of a boiler repair contractor speaks to the quality of work and customer service you will receive. Therefore, check what others are saying about the contractor. For example, review customer testimonials, Google ratings, and suppliers before allowing them to repair your boiler, pressure vessels, or pressure retaining equipment. It is important to remember that these third party endorsements tell the true story of an industrial boiler repair contractor.

FI•CON has R Stamp certified technicians to perform repair work on boiler, pressure vessels, or pressure retaining equipment. FI•CON fabrication and construction services can meet the most challenging projects. By combining these two services and our strategic engineering partnerships, we can design, construct, and customize a project to meet your building and fabrication requirements. We work in a wide range of industries, including manufacturing, ports, mining, education, warehousing, health care, retail, and water treatment. To discuss your next project contact us at ficonusa.com or (386) 792-3060.